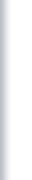

Source: APM Terminals

Author: Sahar Rashidbeigi, Head of Decarbonisation at APM Terminals

Decarbonising our operations is a priority at APM Terminals and to succeed in that, we must overcome some of the main roadblocks for our industry, with fragmentation being one of the most challenging ones.

“In decarbonisation, speed and scale are not just the name of the game (and that of a great book by John Doerr), they’re imperatives in the battle to protect our planet. A significant stumbling block to achieving these twin objectives is fragmentation – a pervasive issue, creating roadblocks at every stage of the journey. It manifests itself in a myriad of ways, but in principle it has two perspectives: structural and self-inflicted.

Structural fragmentation arises from inherent complexities in the system, such as geographical or sectoral spread of emissions, countless involved (and would-love-to-be-involved) stakeholders, and diverse technology pathways. It’s this structural complexity that morphs the challenge into a truly wicked problem. And let’s be honest, it’s precisely this web of complexity that keeps my job exciting and ensures there’s never a dull moment!

Self-inflicted fragmentation, on the other hand, is born from our actions, sometimes unintentionally, such as launching isolated pilot projects, launching far too many pilot projects (for what is technically/commercially mature technology), or actively working against streamlining and standardisation where it is vital.

The enemy of speed and scale

Both forms of fragmentation create bottlenecks to achieving speed and scale. They are relevant at macro level, but also in the context of my day-to-day job, dealing with decarbonisation of container terminals. Here are three examples that highlight these complexities and how we at APM Terminals navigate them at different levels – the organisation, technology pathways and solution design.

To begin with, our organization is the perfect example of structural fragmentation. Imagine our emissions footprint dispersed over 65 terminals worldwide, spread across a staggering 10,000+ pieces of container handling equipment. This equipment varies in performance, age, and expected lifespan, operating primarily within a concession-based business model, which has limited lifetime.

In the coming months, we’ll launch five ambitious pilots across our portfolio. These pilots won’t focus on testing just one or two pieces of battery electric equipment, but complete operational units (consisting of electric Terminal Trucks, electric Straddle Carries and electric Reach Stackers) servicing an entire gang, say SAHAR RASHIDBEIGI.

Our ownership structures further add to the complexity, as we are sometimes sole owners of our assets, while elsewhere we operate in JVs. Factor in the sheer volume and variety of stakeholders we engage with, and it quickly becomes evident that reducing each kiloton of CO2 equivalent is an endeavour in its own right. This landscape clearly makes it difficult to apply one standard approach across the entire portfolio and we strive to find the sweet spot between local and global optimisation, standardizing and simplifying wherever feasible.

Then there is self-inflicted fragmentation, which could be explained by a misinterpretation of the widely accepted wisdom that “in the fight against climate change, there’s a role for every technology, and we need all hands on deck”. This holds true when considering the multi-sector nature and enormity of the challenge; however, it’s a macro perspective. As we delve into smaller subsets, such as ours, which sit outside the traditionally ‘hard-to-abate’ sectors, the landscape shifts. Frequently, there is a singular, not multiple, technological pathway that stands out, due to its technical maturity and commercial viability. Misapplying the ‘all-technologies’ mantra at every level can lead to unnecessary fragmentation.

Focus on electrification

With that in mind, at APM Terminals we have opted for direct and battery electrification of our assets. For technically mature and commercially viable technology (such as Ship to Shore and Rubber Gantry Cranes – STS & RTG), we just proceed with replacing the diesel versions with electric ones. In 2022 alone, we had a pipeline of orders for over 250 items of electric equipment for core operationa. In the coming months, we’ll launch five ambitious pilots across our portfolio. These pilots won’t focus on testing just one or two pieces of battery electric equipment, but complete operational units (consisting of electric Terminal Trucks, electric Straddle Carries and electric Reach Stackers) servicing an entire gang. This proof-of-operation pilot approach is crucial for smooth brownfield decarbonisation, ensuring a seamless, gradual transition from diesel to electric over time. Stay tuned for some exciting news on this front in the coming weeks.

We find ourselves navigating a labyrinth of battery sizes, chemistries, lifespans, charging infrastructures, and battery management software. Let’s face it though – not all of this complexity is unavoidable or ‘structural’. We do have a choice — a choice to facilitate a more rapid, seamless, and consistent transition through standardisation, modularisation, and streamlining, say SAHAR RASHIDBEIGI.

There is also a third perspective I wanted to bring. Even after committing to a single technology pathway, we may still encounter fragmentation. This could result from diverse original equipment manufacturer (OEM) market, and their corresponding supplier markets, as well as variations in equipment performance and weight classes. Some might view these as inevitable — merely the structural reality of specific sectors and sub-segments.

As a result, we find ourselves navigating a labyrinth of battery sizes, chemistries, lifespans, charging infrastructures, and battery management software. Let’s face it though – not all of this complexity is unavoidable or ‘structural’. We do have a choice — a choice to facilitate a more rapid, seamless, and consistent transition through standardisation, modularisation, and streamlining.

Mobilisation is key

Finally, terms like “coordination”, “collaboration” and “mobilising the ecosystem” have become such common refrains in our practice that they risk sounding clichéd. However, having witnessed first-hand the damaging effects of fragmentation, I can affirm that these are not mere buzzwords. They embody the vital necessity of working together to confront the monumental challenge of decarbonisation. The inherent fragmentation of the decarbonisation challenge, coupled with the self-inflicted fragmentation we unwittingly create, underscores the criticality of unified action. A piecemeal approach will not suffice.

The clichés ring true: collaboration is not an option; it’s a necessity. Mobilising the ecosystem isn’t a nice-to-have; it’s the only way forward. Speed and scale aren’t just the name of the game – they are the only way to win it.”

![]()